Cleaner Air Oregon is a health-based permitting program that regulates emissions of toxic air contaminants from facilities based on risk to nearby communities. CAO requires facilities to report toxic air contaminant emissions, assess potential health risks to people nearby and reduce toxic air contaminant risk if it exceeds legal limits.

As part of the Cleaner Air Oregon process, each facility has a dedicated web page to provide communities access to facility information and updates on where it is involved in the process.

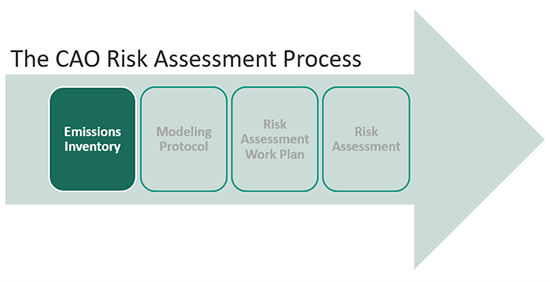

- Each step of the CAO risk assessment process has a section that includes DEQ's communications and deliverables from the facility.

- The graphic below shows where a facility is in the Cleaner Air Oregon Process.

For additional information and history of the program, visit the Cleaner Air Oregon website.

CAO Risk Assessment Process

The Emissions Inventory provides information on all the Toxic Air Contaminant emissions from a facility, and includes information on a facility's operations and activities, as well as fuel and material usage rates. This is often the longest step in the CAO risk assessment process as DEQ needs to verify that all activities have been accounted for, and that the most representative emissions data available are used. In some cases, DEQ will require a facility to perform source testing at this stage if insufficient data is available to estimate emissions. For an introduction to emissions inventories and why they matter, please see

EPA's Fact Sheet.

May 30, 2025: Facility called in to Cleaner Air Oregon.

Aug. 28, 2025: Facility submits an Emissions Inventory and supporting documentation (currently in DEQ review).

About the Facility

Swanson Group Mfg. LLC operates a sawmill and planing mill that manufactures dimensional lumber and green lumber. Logs received by the facility are debarked and sawed to make lumber. Most of the lumber is dried in wood drying kilns prior to shipment; the remainder is marketed as green lumber. The facility has seven kilns that utilize steam supplied by one wood-fired boiler and one natural gas-fired boiler. Wood waste generated from wood working operations is used as fuel for the hogged fuel boiler or transported offsite for sale. The facility has been in operation since 1970.